Reverse engineering starts from the point data obtained from the surface of the model object, which enables us to generate a substitute for the physical object that already exists in the model in the computer. By using the three-dimensional scanning module in reverse engineering, data measurement, fitting, analysis and improvement of existing advanced products can be achieved. This is an efficient means of achieving new product development, and it is also a shortcut from concept design to product development. The three-dimensional scanning module can directly output a variety of data formats for rapid prototype manufacturing and mold processing to support different customer purposes. Moreover, the three-dimensional scanning module provides many functions required from the model or physical scanning to the processing of the desired model, which greatly shortens the development cycle of the mold.

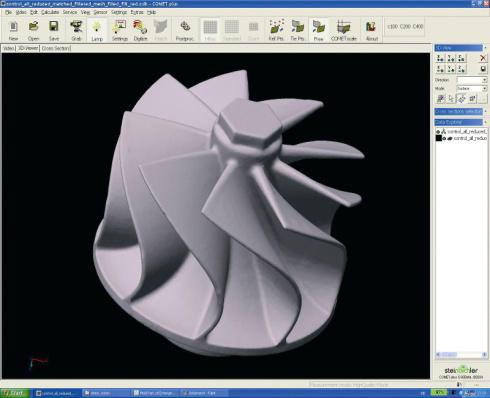

Three-dimensional scanning technology can achieve non-contact measurement, and has the advantages of high speed and high precision. In addition, its measurement results can be directly interfaced with a variety of software, which makes it popular in current increasingly popular technology applications such as CAD, CAM, CIMS. The three-dimensional scanning module is a rapid three-dimensional measurement device. As it can accurately measure the physical objects which are difficult to measure by conventional means (as shown in the figure), and enjoys the advantages of high speed, high precision, non-contact, and convenience, it is applied more and more widely.

The three-dimensional scanning module can easily imitate the streamlined physical objects which are complex in shape and cannot be accurately measured by artificial means. Some high-end parts of China's high-end manufacturing industry are extremely streamlined, and the general measuring instruments cannot accurately measure their surfaces. Reverse technology can collect millions, tens of millions of three-dimensional coordinate data on a small surface, and then can build the surfaces through the software. On an equal-area surface, the more three-dimensional coordinate data, the more accurate the constructed surface will be. The three-dimensional scanning module can scan the plate, sample and model to obtain the three-dimensional data. The data can be directly interfaced with the CAD/CAM software. In the CAD system, the data can be adjusted, repaired, and then sent to the processing center or rapid prototype manufacturing device for manufacturing, which greatly shortens the product manufacturing cycle.